i4Q Data-Driven Continuous Process Qualification¶

General Description¶

Process Qualification is a common industrial application to evaluate machine parameters in relation to quantitative quality measurement. Keeping these parameters in a predefined range is crucial for manufacturing products of the same quality. Therefore, descriptive statistics is required to check samples to a desired level of confidence if all produced goods stay in the same range of quality. Since this approach can only evaluate already manufactured products and is not including a real-time component, all produced goods between the time a failure was identified and the current point of time are classified as waste. To counteract these day-to-day issues, sensor data that describes important process parameters are combined to a predictive statistical model which will forecast the process quality as Cpk-value in a specific time frame to a certain level of confidence. Furthermore, the collection of real-time data enables a continuous as-is evaluation to interact when the prediction was not precise enough.

Features¶

Feature 1: Continuously evaluating process parameter Cpk: reading real-time data streams and presenting them over specified time range or product quantity transformed to non-normality performance index. Furthermore, single parameters can be adjusted by inserting them in a sidebar to create personalized analysis.

Feature 2: Indication of distribution characteristics: to inform the process owner about the distribution over the specified time range or product quantity, a distribution plot and the highlighted confidence interval of the last number of chosen products is displayed.

Feature 3: Capacity forecast and forecast accuracy: as information about the chosen time range into the future, a forecast about the process capacity is made concerning the current conditions of the machine. Additionally, the evaluation criteria of the forecast algorithm are provided to leave the decision about further actions in the process owners responsibility.

Graphical User Interface¶

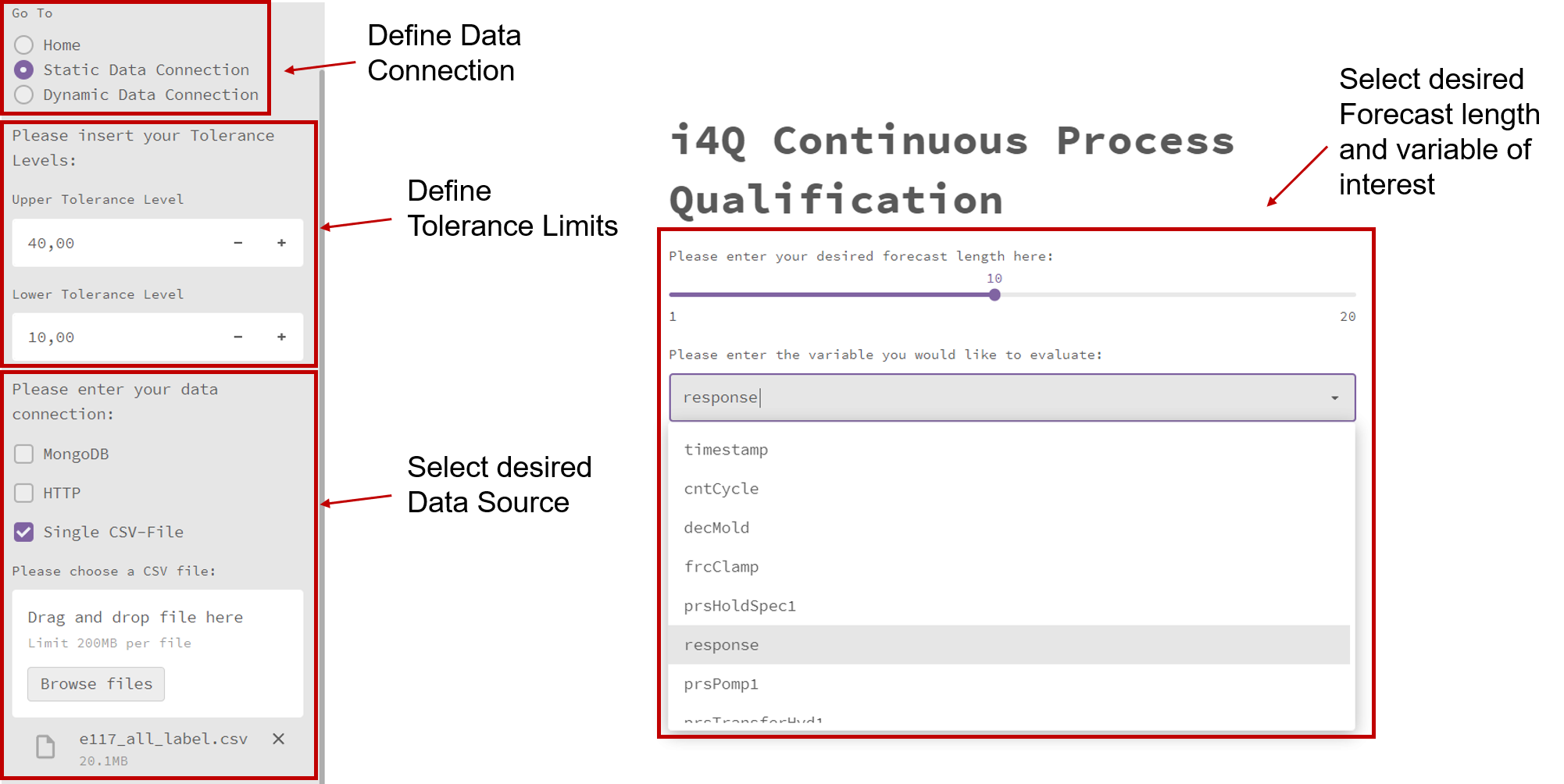

Figure 1: Options to chose in regard the individualization of the GUI when choosing the static data connection.

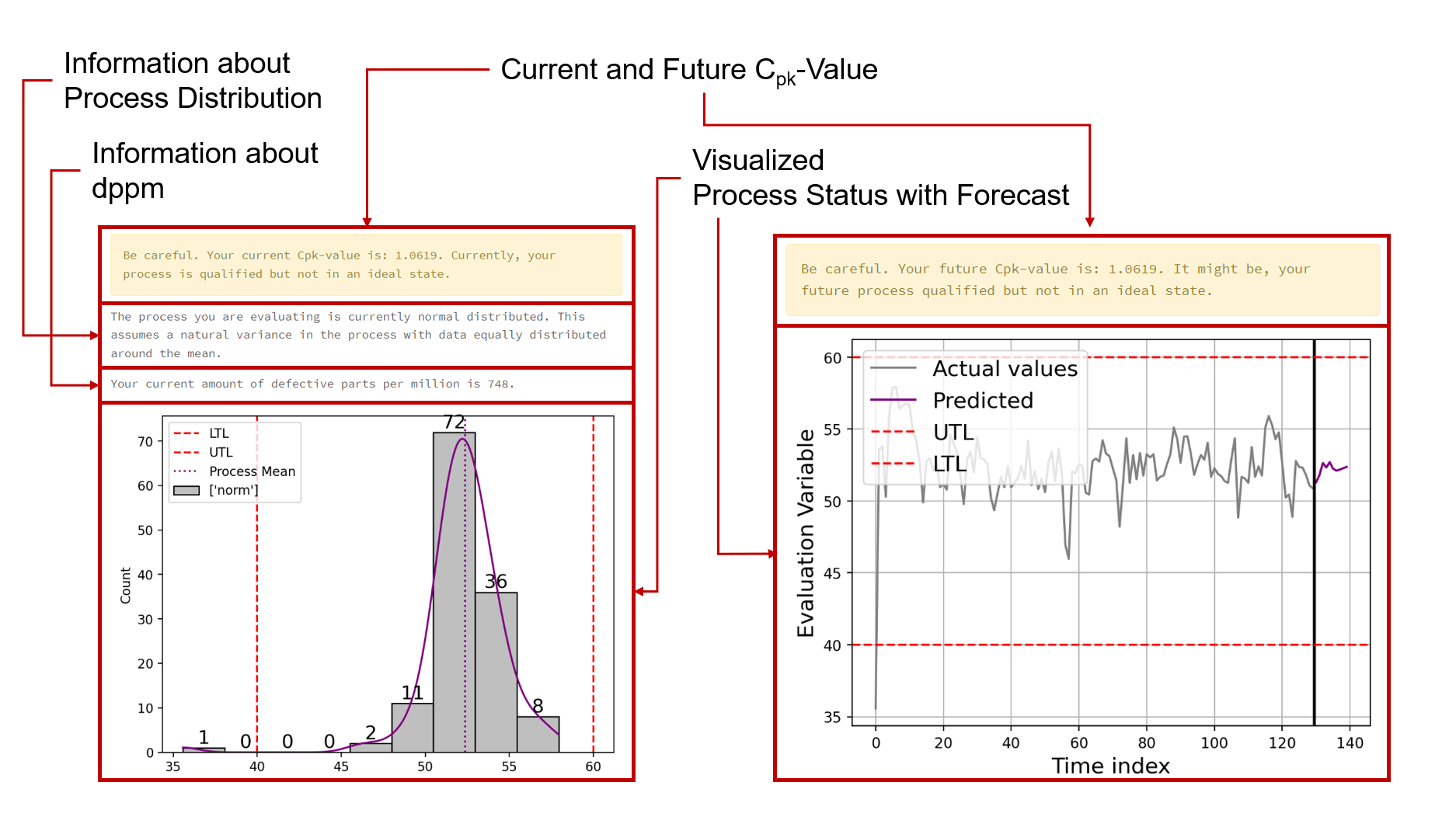

Figure 2: Output to evaluate current and future process qualification.

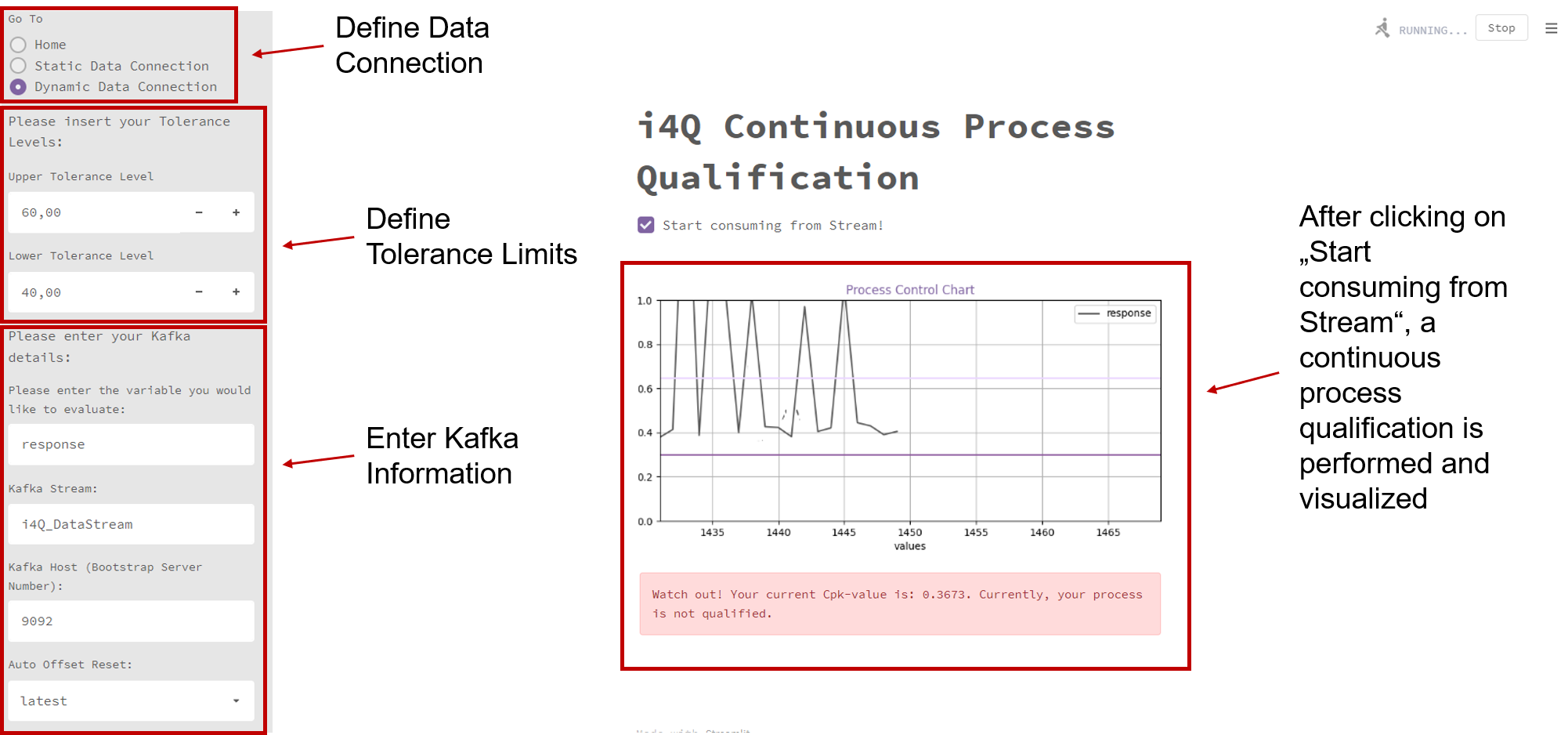

Figure 3: Options to chose and cisualized output in regard the individualization of the GUI when choosing the dynamic data connection.

Comercial Information¶

License¶

There is no licensing involved for using this software.

Pricing¶

Subject |

Value |

|---|---|

Payment Model |

Open-Source |

Associated i4Q Solutions¶

Required¶

Runs as stand-alone solution.

Optional¶

i4Q Security Handler

i4Q Data Repository

i4Q Data Integration and Transformation

i4Q Rapid Quality Diagnosis

System Requirements¶

Docker

Docker-Compose

Installation Guidelines¶

Resource |

Location |

|---|---|

Last release (v.1.0.0) |

User Manual¶

tbd